Why difficult, when it can also be simple:

Automation and manufacturing solutions from Matsuura

The demands on flexibility, individuality and cost-effectiveness continue to increase. So it's nice if you can rely on a specialist who will make your work easier in the future. Our manufacturing solutions for automation and unmanned production are characterized by high flexibility. Through personal advice, we can provide you with tailor-made solutions for efficient production and automation in your company.

Automation Solutions

Flexibility meets progress:

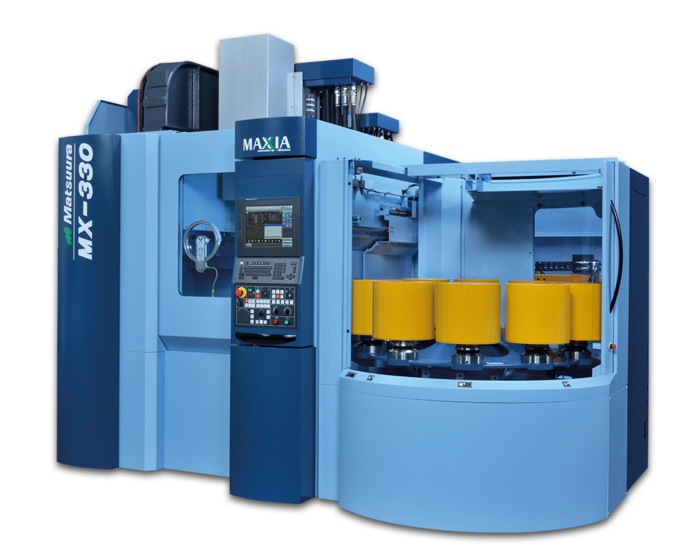

Matsuura's flexible manufacturing cells allow progressive adjustment of manufacturing capacity and can be easily adapted to the machining of other products. Almost every Matsuura machining center can be expanded in terms of pallet and tool quantity. Automation solutions from Matsuura offer circular storage (PC 4 / 5 / 6 / 11), tower storage (PC 12 / 15 / 18 / 40) and shelf storage (PC 42 / 91).

Pallet Storage Systems

Dynamic meets cost efficiency:

Matsuura offers flexible manufacturing cells based on highly dynamic machining centers or machining modules. They can be used to reduce unit costs, especially for manufacturing tasks in automotive and mechanical engineering.

The selection of a suitable production plant is preceded by a careful analysis of the most important evaluation criteria and the machining task. The possibilities are endless. Flexible production cells from Matsuura allow the progressive adjustment of the production capacity. They can also be easily converted to the processing of other products.

Robot automations

Automation meets the future:

Thanks to available features such as automatic loading doors, hydraulics/pneumatics in the machining area or suitable interfaces, Matsuura machining centers can be easily automated with all common robots. Together with its innovative and flexible partners, Matsuura takes automation to a new level. Our partners are CELLRO B.V. and Promot Automation GmbH.

![[Translate to Englisch:] Flexible Fertigungszellen](/fileadmin/user_upload/bilder/produkte/Automatisierung/flexible_fertigungszellen_3.jpg)

![[Translate to Englisch:] FASTEMS Linearpalettensystem Typ MLS](/fileadmin/_processed_/8/4/csm_Fastems_5_a61445b964.jpg)

![[Translate to Englisch:] H.Plus-405 Automation](/fileadmin/_processed_/0/1/csm_Matsuura_3_a07666b829.jpg)